Charpy impact properties of modified tungsten materials

Author:kangbote Time:2023-06-06 11:13:20

The brittleness transfer temperature (DBTT) of modified tungsten materials can be evaluated by several test methods, such as tensile test, bending test, Charpy impact test and fracture toughness test. DBTT depends largely on the test method, strain rate and sample shape. Among them, researchers evaluated DBTT using Charpy impact and tensile tests.

Charpy impact tests were conducted according to EU standards using KLST Charpy V-notched specimens in a vacuum with a temperature range of 200 to 1000 ° C along the L-S(sheet) and L-R(bar) directions (first letter (L) : direction perpendicular to the expected crack plane, second letter (S and R) : direction of expected crack growth).

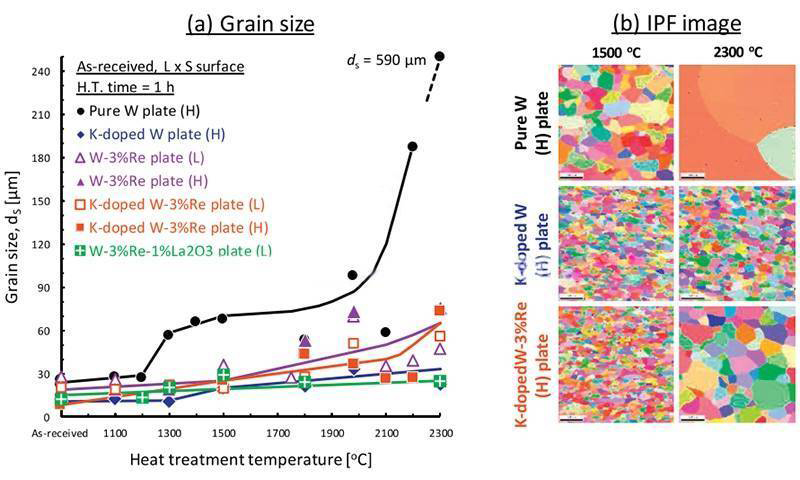

Annealing temperature dependence of grain size in the S direction for pure and modified tungsten materials

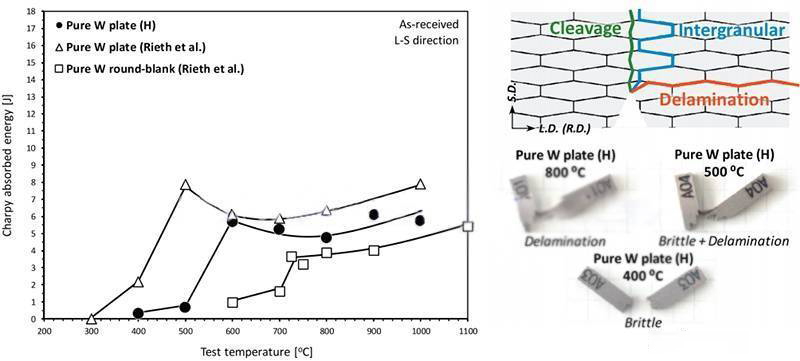

Even though the main chemical composition of modified tungsten materials is the same, the DBTT and shelf energy (USE) varies with the materials, which have undergone different manufacturing methods and histories (e.g., deformation rates).

Most materials show a mixture of brittle and layered fractures below DBTT, and layered fractures above DBTT. In contrast, W bars doped with K show ductile deformation, with small or no cracks above 800 ° C. The relationship between DBTT and grain size (dS) and USE and grain size (dS) is Hl-Petch type. Therefore, those different DBTT and uses cannot be determined by the main chemical composition alone, possibly due to the individual special grain structure depending on the manufacturing method and history.

The DBTT of pure W(H) plate is 550℃; K doped W(H) plate is 350℃; W-3%Re(H) plate at 450℃; W-3%Re(L) plate at 550℃; K-doped W-3%Re(H) plate is 250℃; And W-3%Re-1%La2O3(L) plate at 550℃. For highly deformed materials (" H "), K doping and Re-addition result in DBTT decreases of about 200 and 100℃ and USE increases of about 40 and 30%, respectively.

On the contrary, W-3%Re(L) and W-3%Re-1%La2O3(L) plates show very low absorbed energy compared with highly deformed materials. No significant positive effect of La2O3 particle dispersion was observed in low deformation materials. The appearance of the test specimen shows that the delamination of the low-deformation material spreads rapidly with little plastic deformation of the base metal, while the high-deformation material shows delamination with sufficient bending (plastic deformation). These results show that Charpy impact properties can be improved by K- doping and Re doping when sufficient deformation is applied during rolling and forging.

Image of test temperature dependence of absorbed energy for Charpy impact tests on KLST specimens

In addition, the synergistic effect of K doping and Re doping was obviously observed. In contrast, the dispersion effect of La2O3 particles needs to be clarified by application to highly deformed materials in future work.

Reference source: Tungsten online

.jpg)

封面.jpg)

.jpg)

.jpg)