PRODUCTS

Tungsten Series

Molybdenum Series

Titanium Series

Tantalum Series

Niobium Series

Nickel Series

HOT PRODUCTS

Contact Us

Kaiyuan Avenue,Luoyang,Henan

CONTACT: Xu Jianmin

TEL: +86-379-64687113

FAX: +86-379-64687112

MOBILE:+86-13849934380

EMAIL: sales@moly-china.com

Application

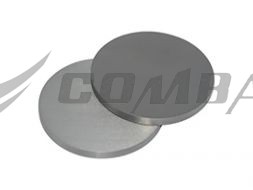

Molybdenum wafer chemical composition is stable, molybdenum content up to 99.9%, accurate size, low surface roughness, can reach Ra 1.6pum below; High melting point, good electrical and thermal conductivity, high strength, linear expansion coefficient and silicon close, good processing performance, is the silicon rectifier complete sets of equipment, semiconductor silicon devices, vacuum tube anode, instrument production indispensable substrate material.

Mode of production

There are three main ways to produce round molybdenum wafer :(1) molybdenum rod wire cutting. The wire-cut production method of molybdenum rod has less geometric loss and higher yield, but the wire-cut efficiency is low. Meanwhile, the grain size of the edge and center of the round surface is easy to be uneven after being rounded, which is still in the experimental research stage. (2) Direct pressing and sintering of molybdenum powder. Molybdenum powder pressing and sintering method yield is higher than (1), but the density is low, the strength is poor, the grain structure is disordered arrangement, users found in use when it is laminated with silicon wafer is easy to crack or fracture, still need to be improved; (3) molybdenum plate punching.

Process

<table cellpadding="0" cellspacing="0" border="1" style=" border-color: rgb(153, 153, 153);> <tbody> <tr> <td style=" text-align:="" center;"="">

Application

Molybdenum wafer chemical composition is stable, molybdenum content up to 99.9%, accurate size, low surface roughness, can reach Ra 1.6pum below; High melting point, good electrical and thermal conductivity, high strength, linear expansion coefficient and silicon close, good processing performance, is the silicon rectifier complete sets of equipment, semiconductor silicon devices, vacuum tube anode, instrument production indispensable substrate material.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)