Top 4 Applications of Tungsten Metal: What You Need to Know

Author:kangbote Time:2026-01-30 01:21:08

Tungsten metal is known as the "teeth of industry" because of its high melting point, excellent density, super wear resistance and good electrical and thermal conductivity. Tungsten from daily household items to cutting-edge technology, play an irreplaceable role in all walks of life. This article will explore the important uses of tungsten.

1. Industrial Applications of Tungsten Metal

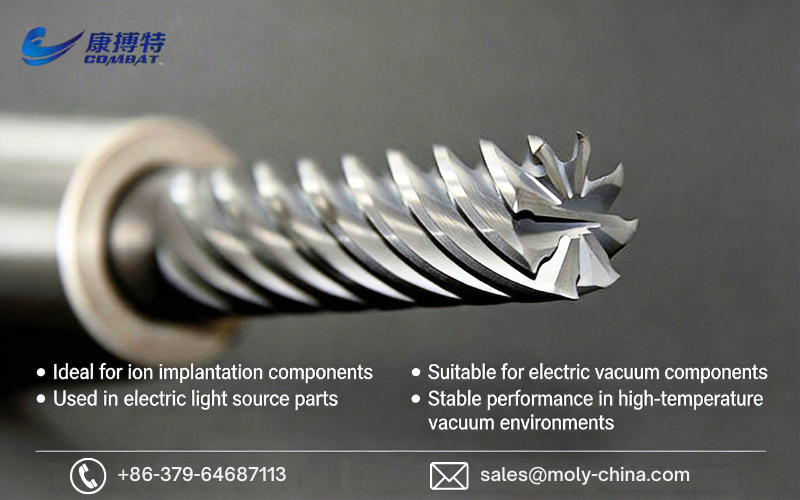

Cutting tools and drill bits

In machining, mining and other scenarios, tungsten carbide is the core material in this field. The tungsten carbide carbide by 85% - 95% and 5% 14% cobalt made by powder metallurgy, still can maintain good performance under high temperature, the cutting efficiency and precision than the traditional tool steels.

Aerospace and Defense

Tungsten alloy is one of the core materials in the field of aerospace and defense. Due to its high strength, high temperature resistance and good machinability, tungsten alloy is an ideal material for manufacturing the basic components of aerospace vehicles. To ensure the safety and efficacy of aerospace and defense system.

Lighting industry

The widespread use of tungsten is manufacturing lamp filament. Its high melting point and heat resistance make it an ideal filament material, which can ensure high luminous efficiency and slow evaporation rate, which can effectively extend the service life.providing consumers with a durable and affordable opportunity.

Electrical contact point

The tungsten alloy is an ideal material for electrical equipment. Commonly used tungsten copper alloy, tungsten silver alloy, both tungsten wear resistance and copper, silver good conductivity, thermal conductivity, can effectively withstand the current through the high temperature and arc erosion, reduce contact point wear and oxidation, prolong the service life of electrical equipment.

X-ray tube

X-ray tube is the core equipment in medical diagnosis, industrial testing and other fields. The performance of its anode target directly determines the intensity and stability of X-ray, and tungsten is the preferred material for anode target.

Due to its extremely high melting point and density, tungsten can withstand the high temperatures (up to thousands of degrees Celsius) generated by high-speed electron collisions, while effectively absorbing excess electrons and reducing stray lines.

Heating element

Due to its excellent resistance to high temperature and oxidation, tungsten has become the core material in high temperature, vacuum or inert gas environment.

Tungsten filament, tungsten rod, tungsten strip and other tungsten heating elements, can work stably in the high temperature environment of 3000℃, and stable chemical performance, not easy oxidation.

Aerospace components

Tungsten alloy was used in the manufacture of engine blade in aerospace, piston, valve and other core parts, using its high temperature resistance, abrasion resistance, high strength, high density features, effectively improve the work efficiency and service life of engine, adaptation extreme environment of high speed, improve the stability and control accuracy of the spacecraft, to ensure the safe and efficient operation of aircraft and spacecraft.

Armor-piercing ammunition

The power of armor-piercing ammunition mainly depends on the density, hardness and strength of the core material, and the advantages of tungsten due to its high density (up to 16.5-19.0g/cm³, close to gold), high strength and non-radioactive can produce more penetrating and chemically stable warheads, thus providing reliable and powerful weapons.

Radiation protection

In the fields of aerospace and nuclear industry, the tungsten alloy has become the ideal choice of radiation protection materials.

In aerospace, tungsten alloys are used to make radiation shielding for spacecraft, and to protect astronauts from cosmic rays in space; In the field of nuclear industry, it can effectively block the leakage of radioactive rays and ensure production safety.

Engine components

In the working process of the automobile engine, the internal parts need to withstand high temperature, high pressure and severe friction. tungsten alloy can effectively improve the power output and service life of the engine.

Compared with traditional steel, tungsten crankshaft can better balance the inertia force generated by the reciprocating motion of the piston, and has excellent high temperature resistance.

Lighting component

Halogen lamp is made of tungsten filament, because of its uniform light, long service life to improve road visibility and safety.

Tungsten alloy is important materials used in the manufacture of LED lamps, can avoid damage caused by light attenuation due to overheating and part, improve the stability of the automobile lighting system and service life.

Balanced counterweight

Tungsten alloy become the ideal material of car balance weight, effectively reduce the vibration.

Compared with the traditional lead counterweight, the tungsten alloy counterweight has higher density and smaller volume under the same weight, which can effectively save the installation space. At the same time, there is no toxic pollution of lead, which is more environmentally friendly.

To sum up, the application of tungsten, beyond the traditional field extends to many industries and products. Its unique characteristics make it become industrial tools, aerospace, electronics, medical health industry indispensable element in a timely manner.

Tungsten's versatility highlights its vital importance for progress and innovation. Understanding its impact on technology and society helps us to see its potential to create a better future. Let us continue to explore the uses of tungsten and embrace its infinite possibilities for a stronger tomorrow.

If you need tungsten supply, please explore our series of high quality tungsten products. Contact us today to discuss your needs.

.jpg)

.jpg)

.jpg)